Latest News View All

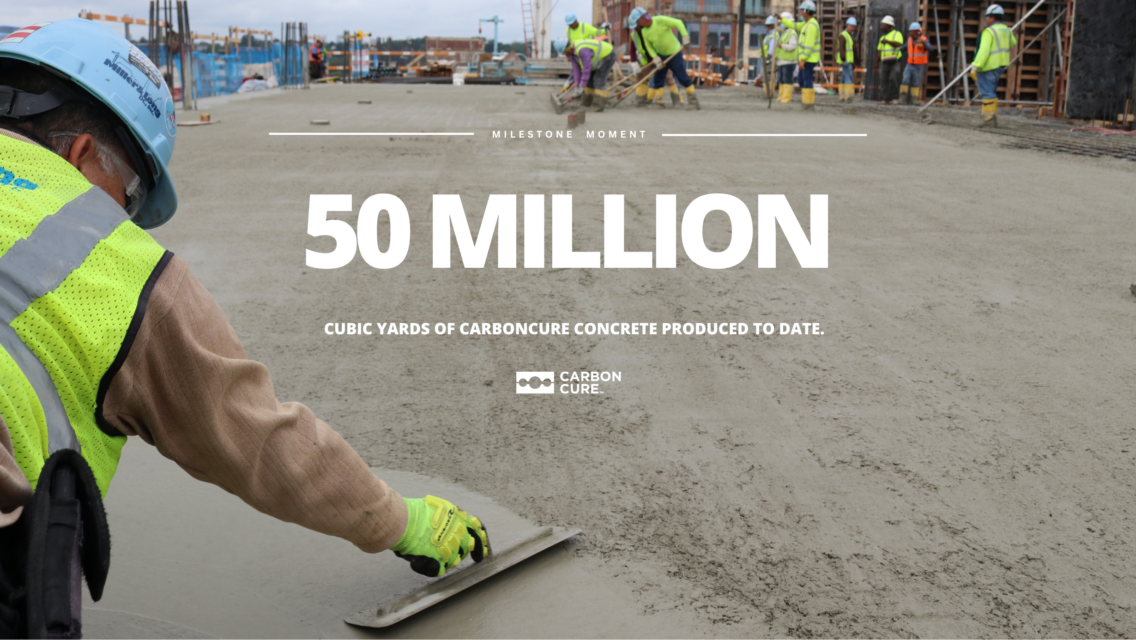

CarbonCure Celebrates Milestone of 50 Million Cubic Yards of Lower Carbon Concrete

See News Release

CarbonCure Technologies Welcomes New CFO

See News Release

CarbonCure Technologies Announces New COO

See News Release

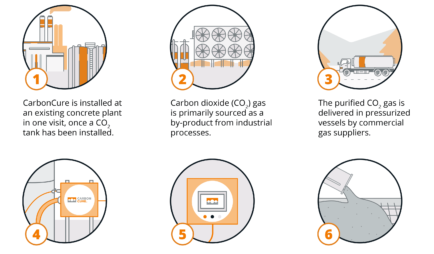

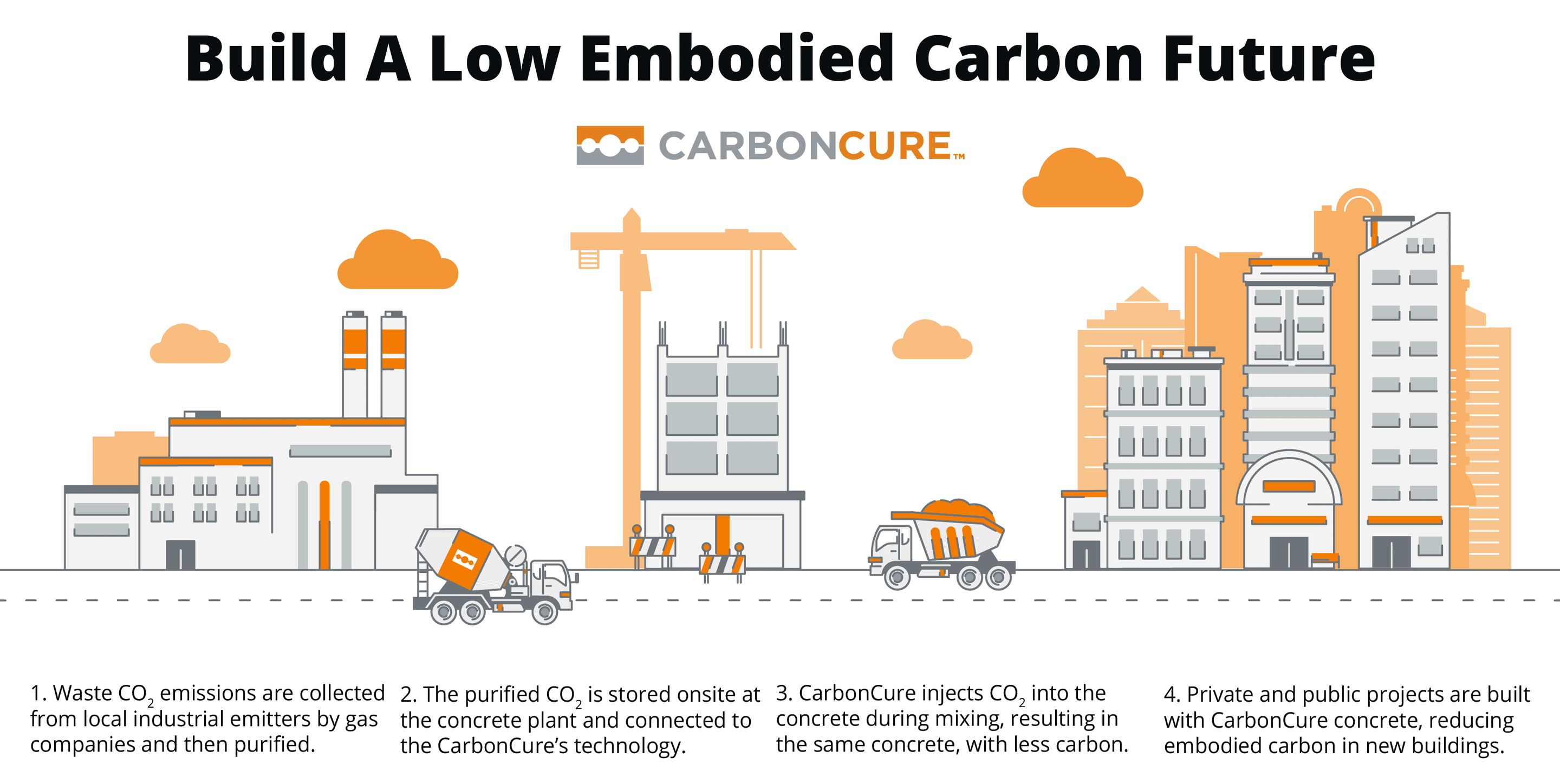

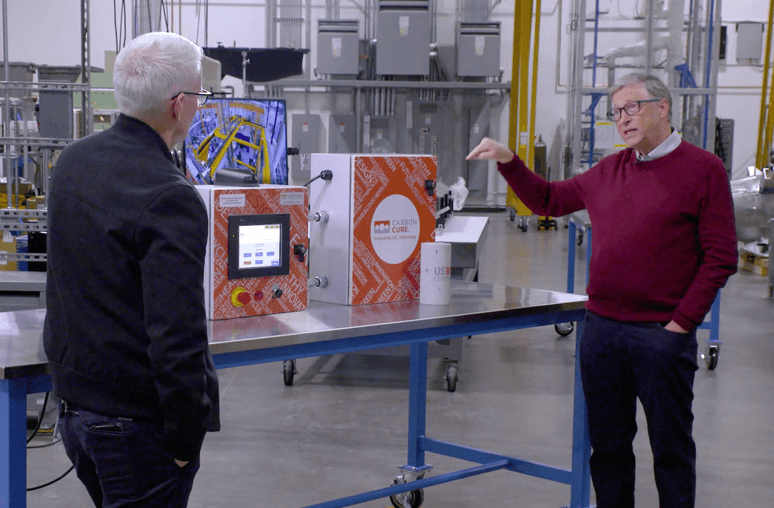

Watch: An Introduction to CarbonCure

Media Resources

Featured Media

Media Kit and Interview Requests

Interested in writing a story about CarbonCure? Download our media kit, which includes a gallery of high-resolution photos, videos, logos and additional resources.

To request an interview, just fill out our Contact Us form. Our team promptly responds to media requests.