As the world seeks solutions to ensure a stable climate and to build a more sustainable future, the field of carbon dioxide (CO2) removal has experienced many technological and scientific advances.

One effective method of CO2 removal is carbon mineralization. For more than a decade, CarbonCure Technologies has developed and deployed carbon mineralization systems that not only permanently store captured CO2 in concrete and keep it out of the atmosphere, our tech also enables concrete producers to manufacture high quality, lower carbon concrete products. In turn, this helps designers and builders reduce embodied carbon emissions in construction.

Common Questions

The building industry continues to work on a standardized approach to accurately measure carbon uptake in concrete and other materials, including natural carbonation that occurs over hundreds of years as well as accelerated carbon mineralization resulting from technologies such as CarbonCure's. This often raises questions about how to accurately compare and validate the few carbon removal techniques that are available today for the industry.

At CarbonCure, we often field questions regarding the uptake of the carbon dioxide injected into concrete versus the carbon dioxide lost during the injection process.

To bridge the knowledge gap, CarbonCure has been working with industry leaders and research institutions to conduct additional studies and develop a standardized methodology for the measurement, reporting and verification (MRV) of carbon mineralization.

CarbonCure uses proprietary technologies that inject captured CO2 during the concrete manufacturing process, where it is immediately and permanently mineralized.

To create more transparency into the uptake of CO2 in the mineralization process, we conduct rigorous testing and have gathered substantial evidence that underpins the efficacy of our technology.

The Experiment

Firstly, we developed a method for measuring low abundance CO2 appropriate for CarbonCure’s ready mix technology.

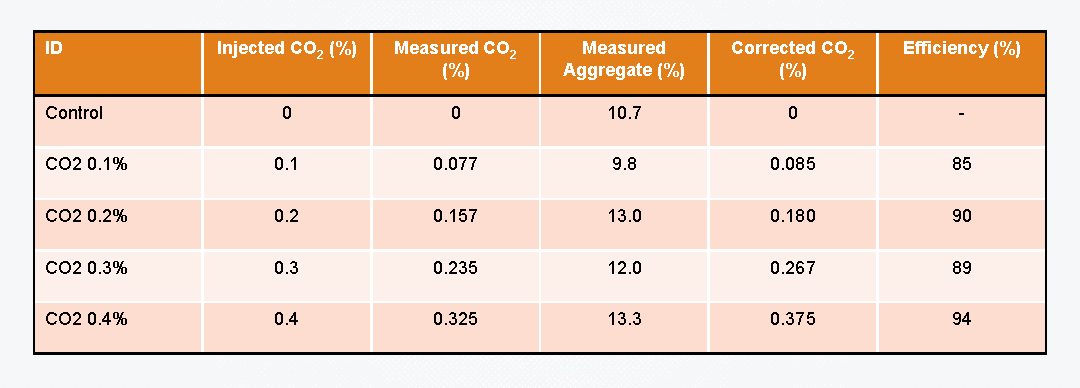

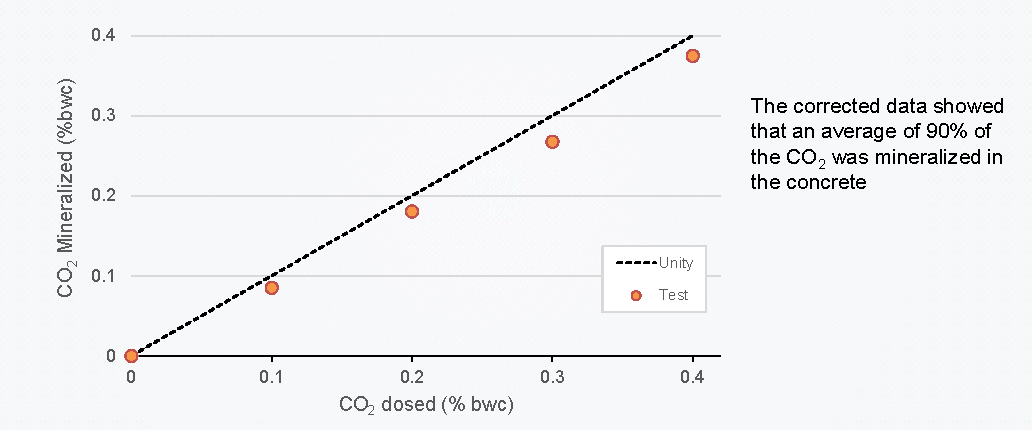

A load of concrete was batched at a local plant and delivered to our lab where a sample was removed to serve as the baseline condition. We then injected CO2 at a dose of 0.1% by weight of cement (bwc), and mixed for five minutes. We also repeated the experiment for incremental CO2 dosage increases to 0.2, 0.3, and 0.4% bwc.

Carbon and X-Ray Diffraction Analysis

For carbon analysis, the concrete samples were tested using an Eltra CS800 carbon-sulfur analyzer, and the average carbon value was used as the result. For accuracy, tests were repeated if two samples differed by more than 0.03%.

To identify that mineralization had taken place, concrete samples were milled using a McCrone micronizing mill, X-ray diffraction (XRD) scans were completed using a Rigaku MiniFlex with a scan range of 0 – 70 (°2⍬), and Rietveld refinement was completed using Smartlab Studios II software.

Note that CO2 is present in other components of a concrete mix (aggregates, cement, admixtures, etc.) so measurements must be adjusted to account for those other factors. These adjustments may involve volumes or dosage rates.

The Results

The results of our experiment demonstrate a strong linear relationship between injected and mineralized CO2.

Standardizing Approaches to Carbon Mineralization Uptake

The need for standardized guidelines is paramount to accurately track the progress of carbon mineralization initiatives, assess their environmental impacts, and understand their contribution toward our global carbon reduction and removal targets.

We believe our methodology sufficiently demonstrates our CO2 uptake and we are collaboratively working with the industry and academia to verify it. As our peers in the market work toward a broad suite of solutions that will change the built environment, cooperation and alignment with measurement will be key to understanding our success.

An Interim Solution

As referenced above, collaboration with industry experts is a key step to standardizing measurement methodologies and testing guidelines. In the interim, we continue to work with independent third parties who can assess and verify our data.

Verra, the world’s leading greenhouse gas (GHG) crediting program and carbon registry, assesses the mineralization data provided by CarbonCure producers for the voluntary carbon market. Verra’s methodology has gone through multiple audits with several third-party organizations to prove the quality, permanence and verifiability, resulting in adherence to carbon market integrity standards established by trusted quality assurance organizations, including the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). Mineralization — and the calculation thereof — is essential to carbon reduction and carbon removal, and CarbonCure counts on the assessment of third parties to validate its measurement.

If you have any questions about our processes or analyses, please do not hesitate to contact us. Or, check out our Technical Reports & Data to learn more.